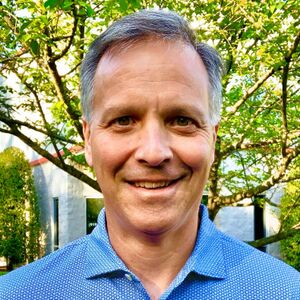

“I think we're getting past the early (fleet) adopter stage,” said Alex Urist, vice president at XCharge North America, an OEM specializing in Level 3 EV chargers and energy storage devices. “Now we're getting into more mainstream adoption. That second wave is coming.”

Andrew Kelley believes we’re in the second or third inning of fleet adoption. Most businesses, even those with small fleets, have made the change or can see it’s coming.

“Small business owners realise they have certain challenges they need to manage,” said Kelley, director of energy solutions at XCharge North America. “They also are aware that they will have to electrify their fleet to some degree, depending on where they are – whether they want to or not.”

Urist’s experience with EV charging goes back to 2020, where he helped co-found Current Electric with a focus on empowering businesses with charging solutions.

Kelley’s expertise reaches back over a decade, with experience in solar, battery, electrification, and distributed energy resources (DER).

With over 40,000 chargepoints deployed across 25+ counties, XCharge has helped electrify fleets and public networks alike.

Given that many businesses are in some stage of conversion, what are the best approaches – and what are the pitfalls? Kelley and Urist recently provided advice based on their expertise as managers of fleet integration.

Reacquaint yourself with your fleet load cycle

Fleet managers need to fully understand their current operation in order to successfully integrate into the EV world.

To do that, they should ask themselves a few crucial questions. Does a vehicle run for eight hours and then sit idle? Does it operate much longer with multiple drivers? Load cycles are crucial because EVs charge during the downtimes.

This data has to be analysed and previous processes rethought. For example, EVs need not be fully charged to leave the yard. A “full tank” might not be required, and in fact, most charge rates slow to a trickle after a battery charges to 90% capacity.

Make the most of what’s available

Managers must be realistic about the charging their fleet will be able to access – at least initially.

“They're not going to need a depot of six to 12 DC fast chargers right off the bat,” Urist said.

The first step to electrifying a fleet is maximising the power that comes to the site. “Look at what power is available on-site,” Urist says. Is there a way to maximise its potential?

XCharge offers a 208 VAC solution – essentially a way to tap into power that is already flowing, and to limit upgrade costs needed to provide charging on site.

A more comprehensive, immediate upgrade is nice, but not always practical – at least not initially. “You’re going to plan for probably at least eight months’ build time, and that’s if all the stars are aligning,” Urist says.

The longer-term upgrade might well be the best solution and should likely be pursued. But in the meantime, get the most out the power that’s available.

There will always be some adjustment

At some point, fleets need to take the plunge. Some parts of the operation will have to change.

Be open to what the drivers are experiencing and understand that some post-launch modifications will be required, regardless of how much planning was done.

“Your delivery folks in a fleet are going to have an entirely different experience with an EV versus a gas vehicle,” Urist said. “What does that duty cycle look like? Do they feel confident so that they don’t have range anxiety? Are they getting enough of the charge time overnight?”

Get professional advice

EV charging businesses and consultants see fleet conversions every day. Their input can make the difference.

“Too often there’s a feeling that there’s a cookie-cutter way to do EV infrastructure,” Urist said. The reality is quite different. Consider relying on the experts instead of tasking your team with identifying every nuance.

You should also understand that your fleet experience might be different than another business’. “A fleet of Chevy Bolts has different needs than a fleet of heavy-duty trucks,” Urist said.

Kelley pointed out that fleet managers often expect to access hardware more than 95% of the time, while the industry standard – unbeknownst to managers – is much lower. Details like this can cause trouble during a conversion.

Don’t downplay the build

Hardware usually has firmly set prices – and it isn’t cheap. That leads some fleets to cut corners during site design and installation. Doing so can have a significant impact on the fleet, Urist said.

“Site design is something that people just don't consider from the get-go,” he said. “You see some really patchworked site design because they're trying to shave costs.”

These designs matter and can, in particular, impact traffic flow. Multiple vehicles can be entering and leaving simultaneously, which can cause bottlenecks and difficulty accessing the chargers.

A proper design also enables easy expansion at a future date.

Optimise operational costs

Once you’ve started to get in the EV space and have some hardware, you can consider the operational cycle. “The next step is looking at ways to mitigate those operational costs,” Urist said.

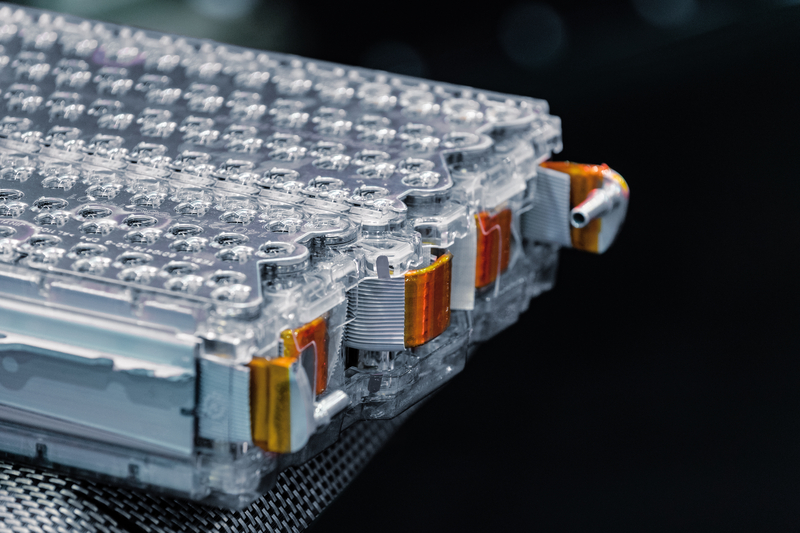

It’s important to have a long-term plan in place. It will drive decisions such as whether to utilise battery-buffered or battery-integrated solutions. Among the differences: buffered cannot send (and sell) power back to the utility; integrated chargers can.

Reliability has a price, too. “If you are in an area that is prone to brownouts and blackouts, and you also know that you need to install electric vehicles ... why don’t you add these valuable battery assets? Provide yourself with some backup power,” Urist recommended. “Folks are starting to think that way. I’m really excited to see what happens in the next months or years with that kind of thought process.”

Get a handle on utility prices

Electricity prices can fluctuate by region, time and other factors. EV charging businesses can help fleets deal with these specifics.

“We work diligently to ensure that we are aware of all the different revenue streams possible in a certain region,” Kelley said.

That can include monetisation of the equipment and other value streams. Integrated batteries can store energy for later use or even to sell it back to the utility.

Summary: Fleet adoption is advancing

Kelley expects to see big progress in the next six months to a year.

“It’s a pretty tight time frame, but I think so. There are lot of variables we don't have control over, but electrification is happening. There are a lot of articles about how strong things are going, or if they're softening or cooling off, but the trend is still positive.”

Urist is also optimistic. “Right now, we're in a really cool part of history, where decarbonising the grid is becoming the most cost-efficient way to operate your fleets.... We're excited to be at the forefront of this technology.”