Leaders of the start-up were joined by Gov. Andy Beshear, local business and community leaders, and EV battery industry executives during the event in Hopkinsville, Ky.

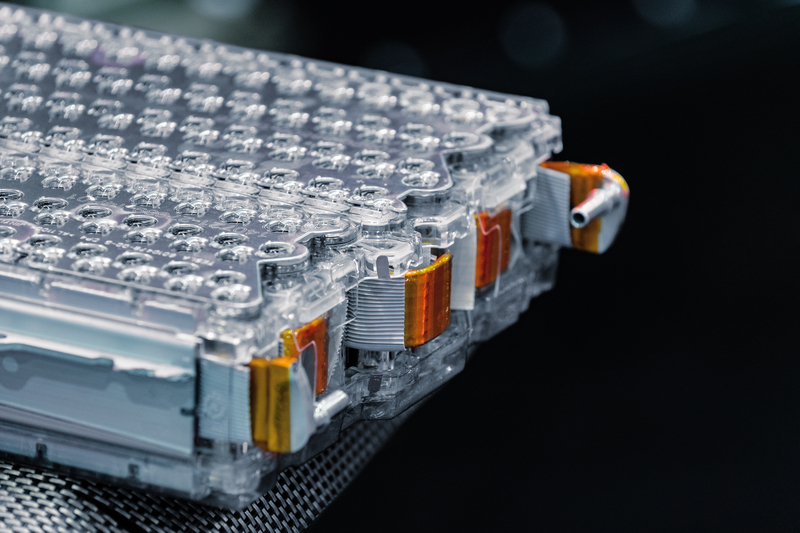

The facility will help meet North America's growing demand for lithium-ion battery materials, specifically engineered precursor (pCAM) and battery-ready cathode active materials (CAM). When finished, the Apex 1 facility in Kentucky will produce enough pCAM and CAM to equip 250,000 EVs per year.

Ascend Elements plans to invest close to US$1bn in the 140-acre campus and 500,000-square-foot manufacturing facility. The first-of-its-kind facility will be home to the company's innovative hydro-to-cathode direct precursor synthesis process technology — said to be the most efficient and economically compelling way to return recycled battery materials to the battery supply chain.

This closed-loop system generates minimal waste and carbon emissions compared to traditional cathode manufacturing. With potential expansion phases, the facility will employ up to 400 people.