Members of the Tesla Owners Club UK took to social media to vent their frustration with the lengthy queues in Hertfordshire, Westmorland, Cumbria, and Telford. Up to 40 cars were reported to be queuing for a charger at Westmorland, northwest England. The queues happened as millions took to the roads for the festive holiday period.

As reported here on 6 January, The Society of Motor Manufacturers and Traders (SMMT), pointed to the government’s EV Infrastructure Strategy forecast that the UK would require between 300,000 and 720,000 chargepoints by 2030. Meeting just the lower number would still require more than 100 new chargers to be installed every single day. The current rate is around 23 per day.

According to the comparison website Next Green Car, there were 420,000 pure-electric cars on UK roads at the end of February 2022. These were served by only 30,290 charging points across Britain, of which 5,494 were rapid chargers.

Britpave, the infrastructure industry association, believes that the festive season charging chaos, which was widely reported in national media, supports the need for a different charging solution.

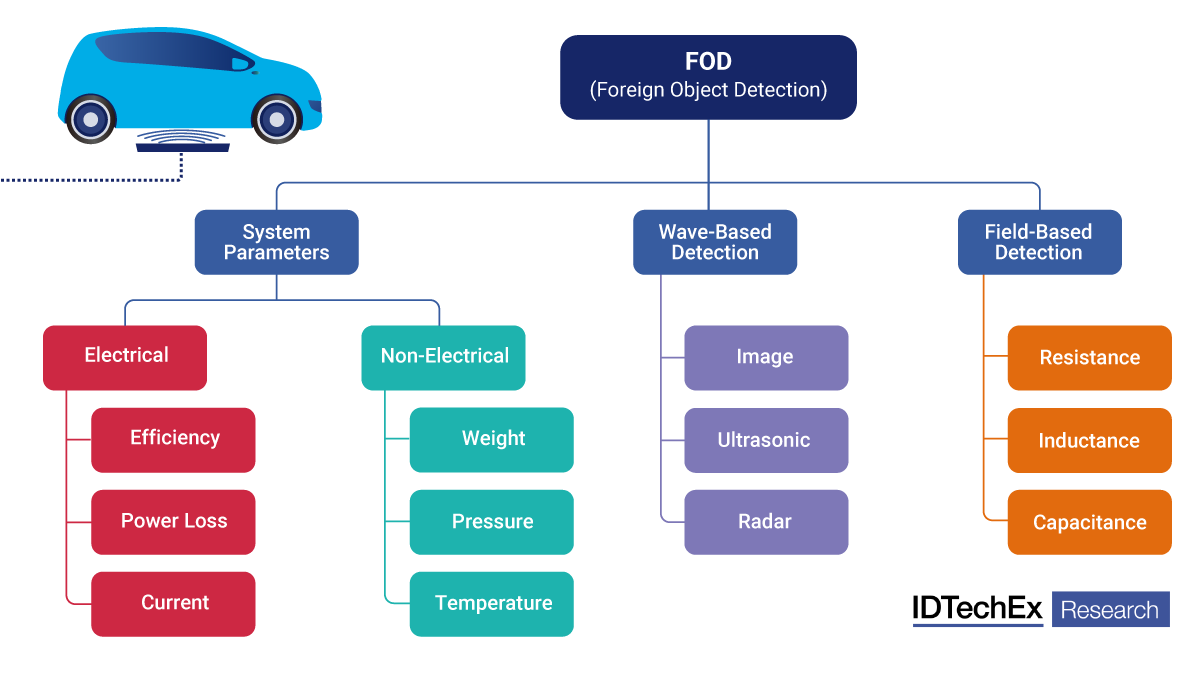

Joe Quirke, chairman of Britpave, believes that eRoads that charge EVs as they pass over them are the solution. Vehicle batteries would be charged inductively via wireless systems using magnetic coils installed in the road surface that feed an electric charge to magnetic coils fitted on a vehicle’s undercarriage and so charge the battery.

“The long-term strength and performance of concrete makes it the better option for such roads as they do not need regular maintenance and in hot summers - such as the summer that we have just had - do not melt, unlike asphalt roads. Road surface melting could dislodge and compromise the embedded coils,” explained Quirke.

Pointing to other developments for concrete eRoads which involved making the road itself conductive, Quirke said, “In Australia, Talga Resources are mixing graphene into concrete to make the road conductive, whilst in Germany, Magment – concrete containing magnetic ferrite particles – is being developed for road construction.”

“If the potential for electric vehicles is to be realised then there must be a ready and easily available power supply. Concrete eRoads could provide such a supply. We would welcome a round table discussion with Government, National Highways, car manufacturers and coil suppliers to examine potential concrete eRoad alternatives to chargers,” Quirke added.