Cambridge-based Nyobolt adds this means that a full charge enables the prototype to achieve a range of 155 WLTP (Worldwide Harmonised Light Vehicle Test Procedure) miles, twice the speed of most of the fastest charging vehicles today. Furthermore, as the first four minutes are at a constant current of 500A, this provides 120 miles of range after just four minutes of charging.

Founded in 2019, Cambridge-based Nyobolt has leveraged its next-generation patented carbon and metal oxide anode materials, low impedance cell design, integrated power electronics and software controls to create power dense battery and charging systems. These support the electrification of high-uptime industrial and automotive applications such as heavy-duty off-highway trucks, EVs, robotics and consumer devices that demand high power and quick recharge cycles.

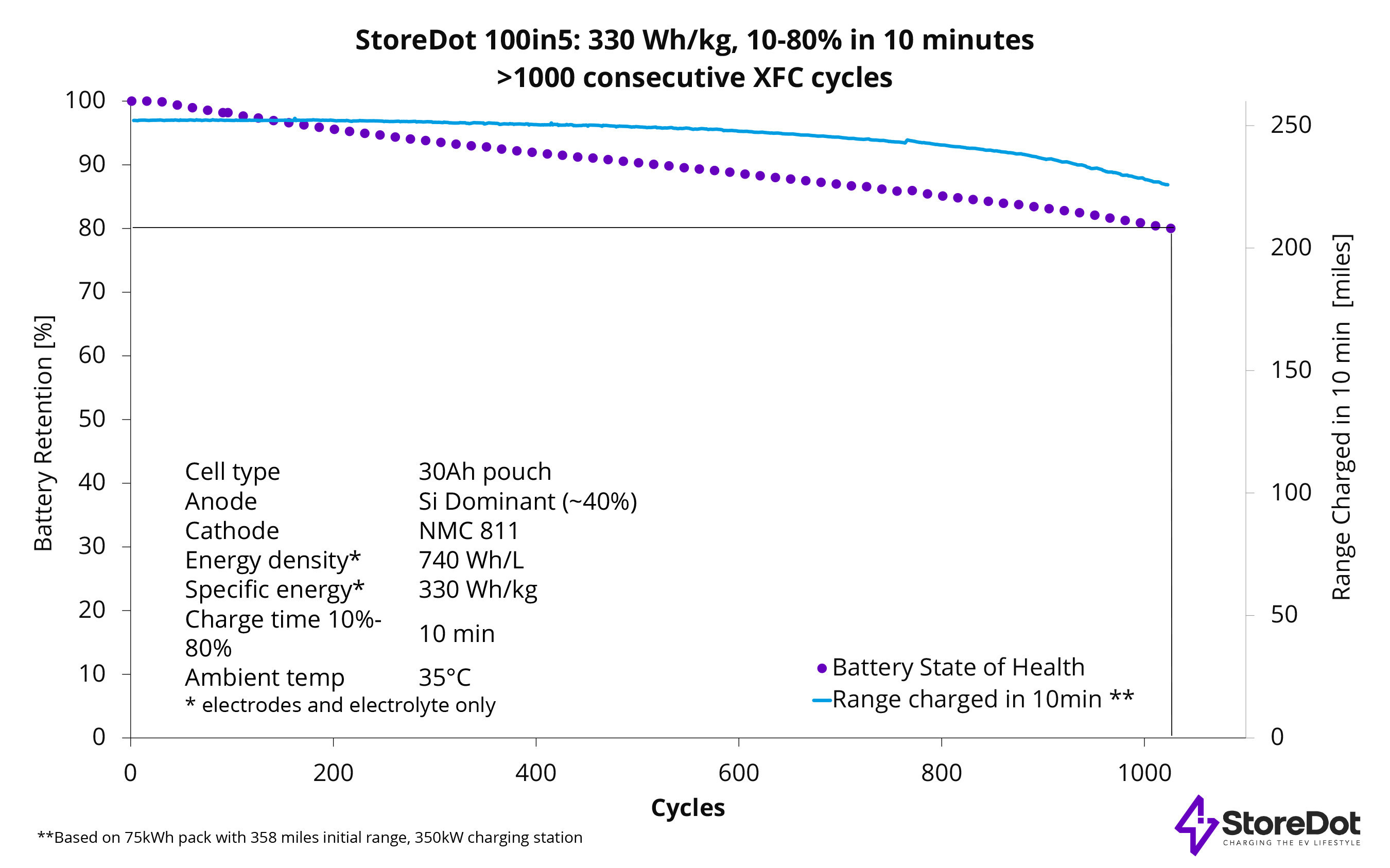

Nyobolt says its technology also solves the levels of degradation that typically come with supercharging lithium-ion batteries. The company's 24.5Ah cells have already successfully completed over 4,000 full DoD (Depth of Discharge) fast charge cycles, equating to over 600,000 miles if used in the Nyobolt EV pack, while still retaining over 80% battery capacity. This is many multiples higher than the warranties of much larger EV batteries on the road today.

Independent OEM testing has confirmed its 2.6Ah cells can achieve over 4,400 cycles with a 12C charge and 1C discharge at 23°C. Crucially, the cell internal resistance rises by only 50% after 4,400 five-minute charge cycles. This is lower than the industry accepted end of life values for EV cells, which is typically twice the initial value.

“Despite some OEMs showing fast charge times in the region of 15 minutes, a closer inspection reveals the charge is usually across a limited SOC region specifically chosen to limit the amount of life taken out of the cell; for instance, between 20-80%,” says Nyobolt co-founder and CEO Sai Shivareddy. “Typically, the charge profile will only hold these peak charge levels for a short amount of the charge time. Nyobolt’s low impedance cells ensure we can offer sustainability, stretching out the battery’s usable life for up to 600,000 miles in the case of our technology demonstrator.”

The 35kWh battery pack in the Nyobolt EV prototype not only adds miles faster but the compact battery pack size benefits car makers and motorists, enabling energy efficient electric vehicles that are cheaper to buy and run, and crucially use fewer resources to manufacture.

The company says it is "no accident" that the Nyobolt EV is a sports car weighing just 1,250kg; it underlines that Nyobolt can also enable the automotive industry to return lighter, better handling sports cars. “We can enable OEMs to build excitement back into the segment, which is literally weighed down by legacy battery technology currently,” says Shane Davies, Nyobolt director of vehicle battery systems.

“Our Nyobolt EV demonstrates the efficiency gains facilitated by our fast-charging, longer-life battery technology, enabling capacity to be right-sized while still delivering the required performance,” adds Davies. “Nyobolt is removing the obstacle of slow and inconvenient charging, making electrification appealing and accessible to those who don’t have the time for lengthy charging times or space for a home charger.”

Just 12 months after revealing the concept, a driveable Nyobolt EV prototype, engineered together with UK design and engineering consultancy Callum Designs, will advance testing of the technology in the real world, enabling OEMs to experience Nyobolt’s ultra-fast charging technology first hand.

Whilst the priority use for this Nyobolt EV is showcasing and testing the battery technology, Callum’s team has engineered it so that low volume production – for road or track use – is possible. Nyobolt’s battery assembly plans are more advanced and could be in production at low volume within a year, ramping to 1,000 packs in 2025. Nyobolt’s flexible manufacturing model enables volumes of up to two million cells per year. Nyobolt’s battery will also comply with the EU’s Battery Regulation requirements once in production.

The Nyobolt EV’s architecture also highlights how it could be retrofitted to existing EV platforms, bringing a step change in charge time and battery cycling life. The Nyobolt EV’s battery modules are cooled via cold plates with a water/glycol mix. The battery circuit uses an AC compressor and condenser and a battery chiller, compatible with other performance vehicles, and results in a near standard module and battery pack. The limited heat generation – no more than 60°C during a fast charge or a performance drive – is influenced in the main by the ultra-low impedance cell chemistry.

Nyobolt says it is already in conversation with a further eight vehicle OEMs about adopting its technology. Alongside automotive applications, Nyobolt’s fast-charging technology is set to be deployed this year in robotics with other applications such as heavy-duty commercial vehicles seeking low downtime and high-productivity, also advancing.