The company suggests that global automotive manufacturers should be considering interim technologies in the medium term, such as semi-solid batteries.

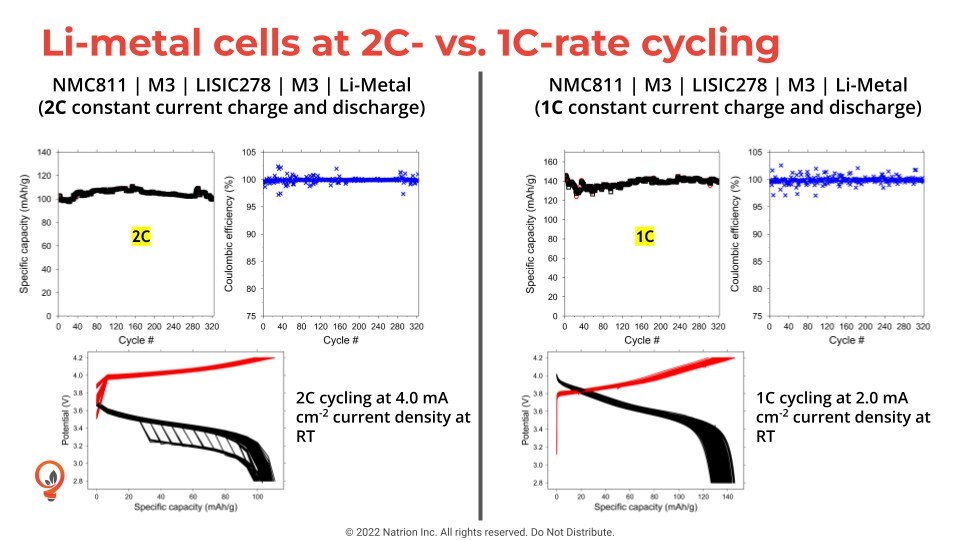

Solid-state-batteries promise cost-effective fast and safe charging batteries, with high energy densities. However, they remain a work in progress and still face significant challenges before they can be manufactured at scale. A solid-state battery uses solid electrolytes instead of the liquid or polymer gel electrolytes found in current technologies such as lithium-ion or lithium polymer batteries.

"It's crucial that leading battery developers like StoreDot give global automotive manufacturers a realistic and hype-free roadmap for the introduction of extreme fast-charging battery technologies,” said Doron Myersdorf, StoreDot CEO. “Right now, despite some of the bullish claims by our rivals, all-solid-state batteries are still at least 10 years away. They are certainly no silver bullet for any vehicle maker currently developing fast charging electric vehicle architectures.

"We believe a more practical step is the introduction of semi-solid-state batteries which we are targeting for mass production by 2028. These will be advanced, safe, high performing cells that can achieve 100 miles of charge in just three minutes. They have the additional benefit of requiring a simpler and less challenging manufacturing process than all-solid-state technologies," Myersdort said.

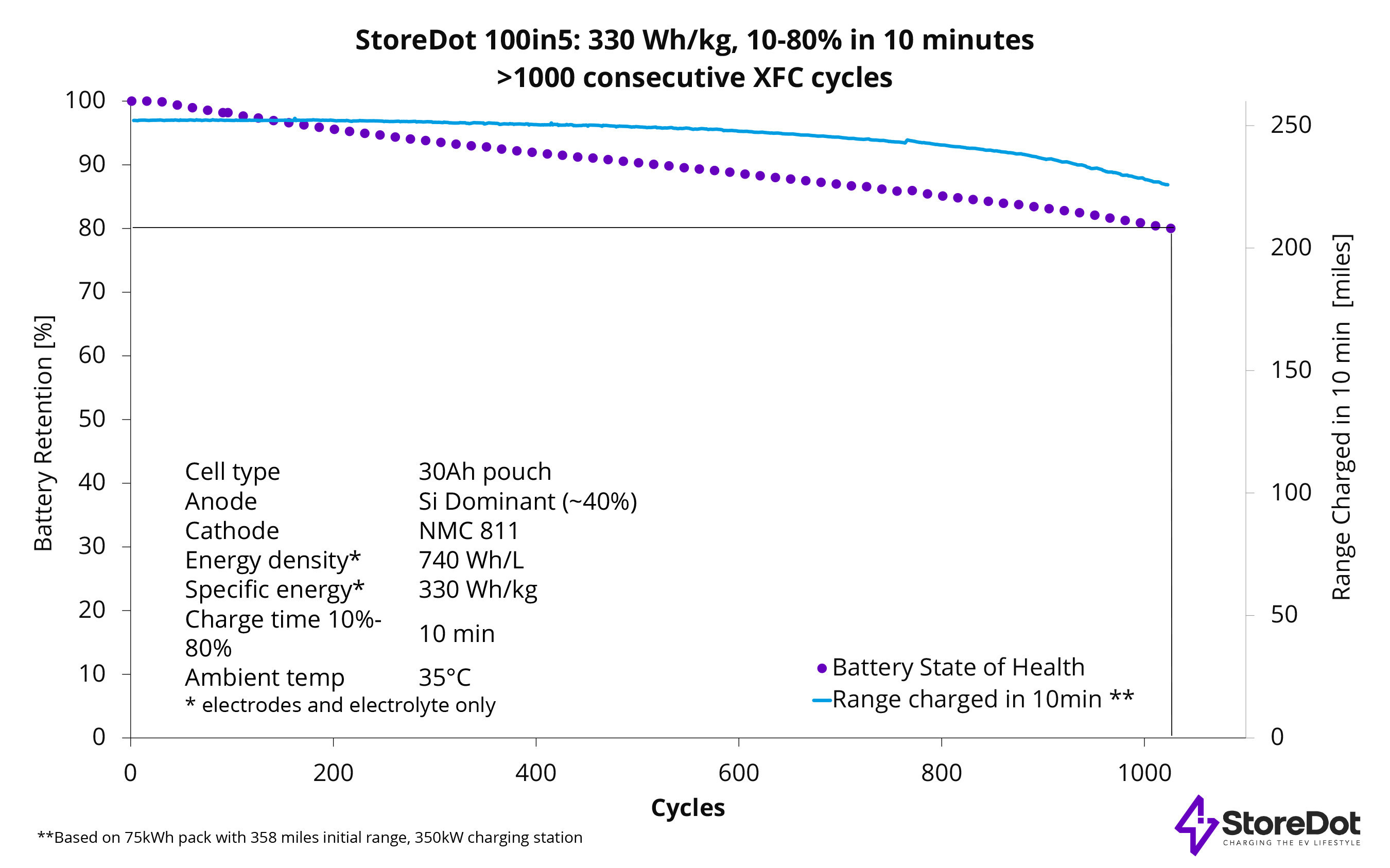

Last month StoreDot proved the superior performance of its extreme fast charging battery cell technology by delivering cells that exceeded 1,000 cycles in production ready EV form factor. These cells are now being shipped in pouch format to StoreDot's global automotive OEM partners for intense real-world testing and exhibit the promised '100in5' EV performance, allowing drivers to charge consecutively 100 miles of range for each five minutes of charging.