Designed to produce over 250,000 units in 2022 and over one million in 2030, the 130,000 square foot factory will manufacture all the company’s chargers in the US which will serve multiple segments of EV charging including residential charging, bidirectional charging and hyper fast highway corridor charging.

“Today only 3% of the chargers required globally for the next decade have been installed, showing the magnitude of the need for innovative and reliable charging solutions,” said Enric Asunción, CEO of Wallbox. “Bringing Wallbox’s manufacturing capabilities to the US significantly bolsters our ability to meet US needs, deliver to public funding programs and drive the energy transition.”

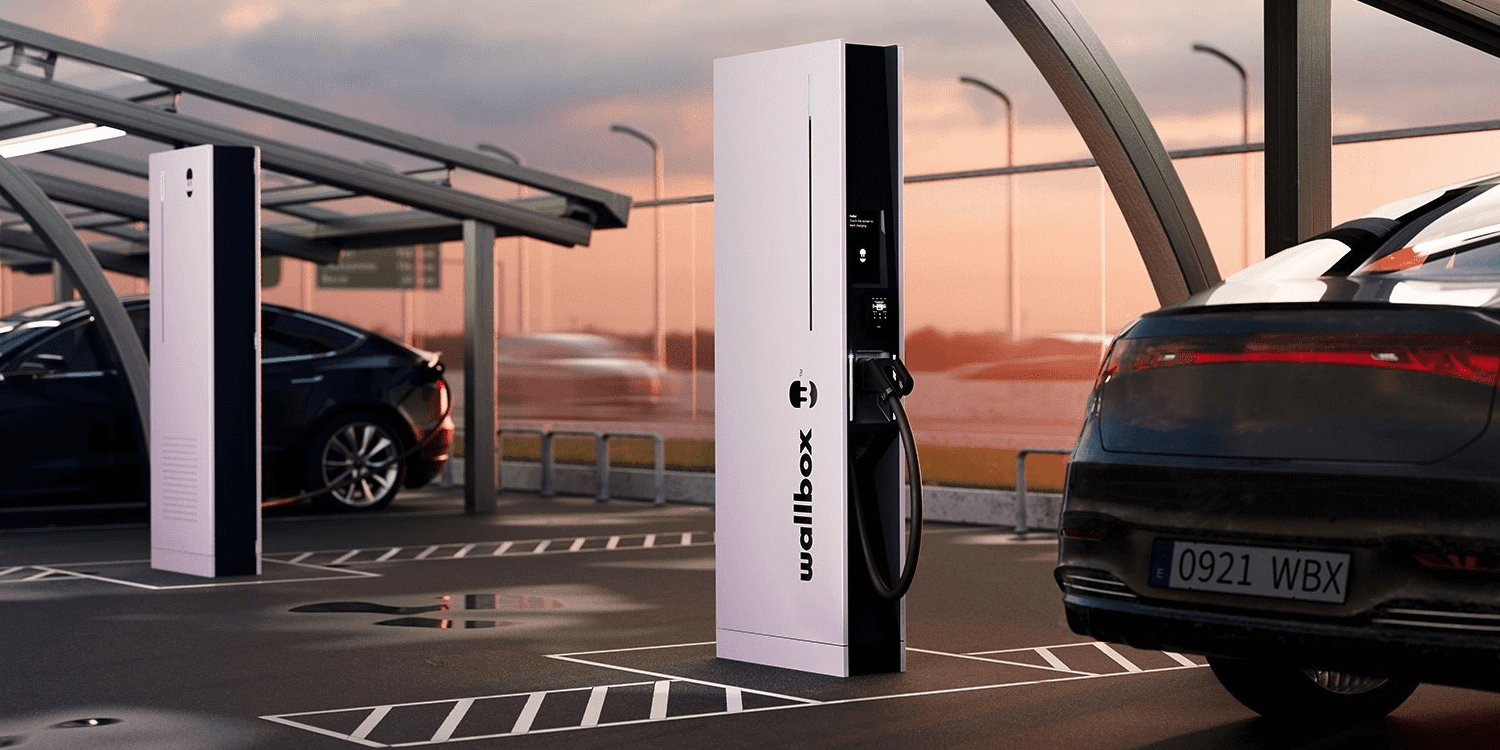

As part of the factory opening, Wallbox offered a live demonstration of Hypernova, its hyperfast DC charging solution that delivers up to 400kW of charging power, making it ideal for highway corridors. The charger can add up to 100 miles of range in five minutes of charging.

Hypernova has a centralised power system that can feed one or multiple dispenser units. The innovative design allows for a wide variety of configurations that can be upgraded over time, including the addition of more power modules or dispenser units to the installation, thereby allowing charging services operators and fleets to match current and future demand. It offers a seamless user experience with its compact size, integrated cable management system, interactive lighting system and sunlight readable touchscreen.

The Arlington facility is now producing Pulsar Plus, Wallbox’s global smart home EV charger that is compatible with all EVs. In 2023, the factory is expected to begin the production of Hypernova.