Bringing a new battery cell product to market is hugely complex and time-consuming. R&D processes are lengthy, comprising design of experiments (DoE) using first-principles simulations to discover new electrochemical designs, which are tested through physical trial-and-error in a laboratory. There are many steps in the cell manufacturing process that can affect not only the rejection rate, but also the performance of the cell.

Hexagon’s new electro-chemical battery design solution integrates Fraunhofer ITWM’s Battery and Electrochemistry Simulation Tool (BEST) solver within Hexagon’s Digital Materials suite, enabling efficient multi-physics exploration of cell designs while accounting for effects from manufacturing processes.

This “virtual laboratory” has significant cost and productivity benefits. Through a single user interface, customers can model the microstructure of the electrodes through to the complete assembly of the cell (electrolyte, separator, active material, binder, current collector) from an embedded library of battery materials, and explore the impact that alterations in material properties and battery microstructure have, including:

Guillaume Boisot, Senior Director Materials & Platforms, commented: “The design and development of cells involve significant challenges due to the complex trade-offs between materials and electrochemical design, mechanical design and manufacturing processes. Much of this complex process has historically relied on trial and error, but through our partnership with Fraunhofer ITWM we believe we can help R&D teams pursue better performing battery cell designs, and develop them faster with rapid feedback from prototypes.”

Subham Sett, Vice President Multiphysics at Hexagon added: “Battery performance and quality are competitive differentiators, particularly in the automotive market. We’ve invested in our thermal management and runaway simulations, and with this new addition we believe we can help manufacturers get a more holistic view of these multiphysics interactions on their journey to shift left in the design process.”

Dr. Jochen Zausch, Fraunhofer ITWM commented : “We have enjoyed an excellent technical collaboration to bring our highly trusted BEST battery electrochemistry solver capabilities into Hexagon’s innovative material modelling software, and we look forward to helping drive forward new battery innovation faster with this comprehensive simulation workflow.”

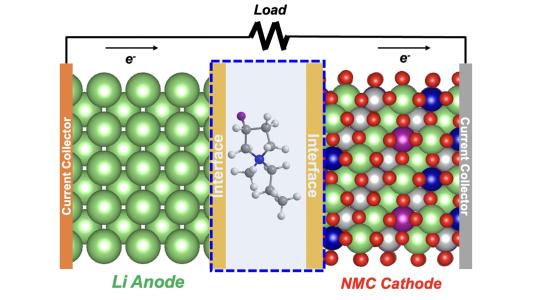

The new solution integrates Frauenhofer ITWM’s BEST solver into Hexagon’s Digimat material behavior modeling software – part of its HxGN Digital Materials suite. From a single user interface, users can simulate the electrochemistry of a cell’s constituent microstructure, electrolyte, separator, active material, binder, and current collector for common lithium-ion cell configurations, as well as zinc and sodium battery chemistries, using Fraunhofer ITWM’s advanced electrochemical modelling techniques.

Digimat includes a library of common material properties that can be extended within the software or using Hexagon’s MaterialCenter and Materials Connect material data management software. Microstructures can be either imported from CT scan analyses using VGSTUDIO MAX or created directly in Digimat.

Additionally, battery design teams can apply their microstructure model developed in Digimat to further investigate mechanical property characterization. Macro-scale material behavior can be assessed using a Representative Volume Element (RVE), extending the model’s capability for structural analyses of the cell by embedding a simplified Digimat material model into the relevant mechanical analysis software. In this way, mechanical engineers can evaluate the mechanical performance of the jelly roll to optimise the mechanical design and safety of the battery based on accurate material properties.

Hexagon provides digital reality solutions, combining sensor, software and autonomous technologies. The company says its smart manufacturing technologies provide several solutions for e-mobility providers to optimise and validate battery designs using CAE simulation, ensure robust EV battery manufacturing processes with process simulation and execution tools and verify components and battery systems through non-contact inspection and non-destructive testing techniques.