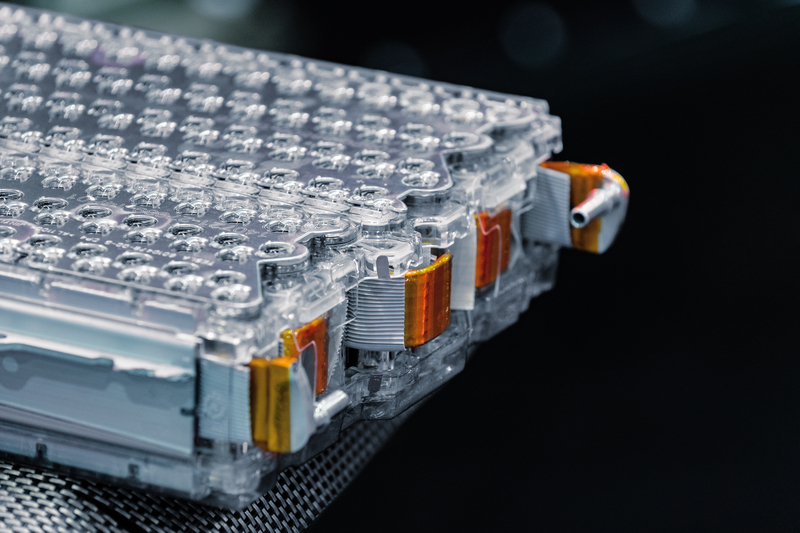

In its response, Ionic MT strongly recommended the department further invest in research and development to enable rapid commercialisation of halloysite-derived nano-silicon. The company adds that it enhances lithium EV batteries to charge eight times faster than current EV batteries and have up to 10 times the capacity of existing EV batteries.

Ionic says halloysite nano-silicon can replace graphite (or work in tandem with it) and is a game-changer for the industry. It adds that the material generates far greater performance by reducing the swelling, cracking, and deterioration of traditional batteries.

Halloysite-derived nano-silicon is also already commercially viable, and the nano-silicon feedstock material derived from halloysite is a small fraction of the cost of the traditional silane gas-derived nano-silicon feedstock material. Finally, halloysite is plentiful in the United States, with millions of tons available (and growing) at the Ionic MT site. Ionic has commissioned its nano-silicon pilot plant facility to produce Halloysite derived nano-silicon today and has large-scale production in construction, slated for second half 2023.

"Halloysite-derived nano-silicon represents a step change in capacity and fast charging capabilities for lithium-ion batteries,” said Jake Entwistle, director of battery materials at Ionic. “To meet the growing demand for electric vehicles over the coming decade, innovation and new mineral reserves must be brought online. Ionic embodies this. Not only that, our mining operation and novel chemical process is non-intensive and produces critical mineral by-products to give a next generation battery material in a green manner.”