Together, the two companies say they aim to nurture a European battery ecosystem that supports Europe’s efforts to achieve climate neutrality by 2050.

Under the MoU, the two companies will establish best practices for virtual, end-to-end development of products and manufacturing processes that improve innovation and efficiency and mitigate technical risks throughout the product lifecycle. Dassault Systèmes’ 3Dexperience platform will be the catalysts for establishing new methodologies and ways to innovate sustainably in areas such as product, process and flow simulation, supplier collaboration and total quality management.

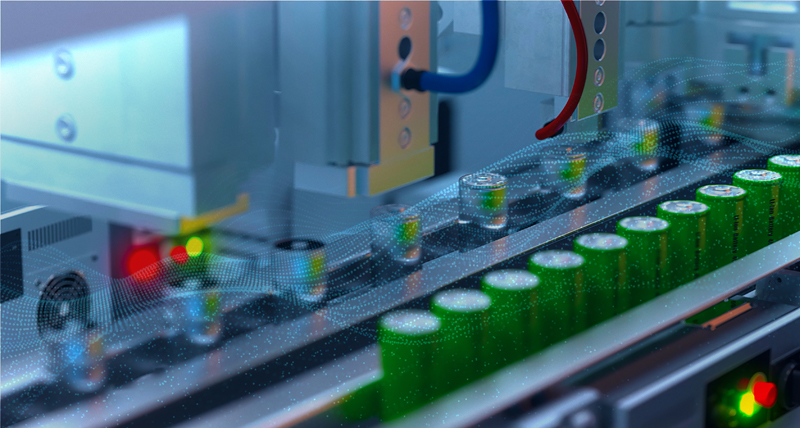

Verkor can benefit from long-term support from Dassault Systèmes’ technical teams while developing its expertise on the 3Dexperience platform, to drive unprecedented levels of virtualisation when it builds its first gigafactory in Dunkirk, France. Verkor will use the platform to build the virtual twins of its batteries and the manufacturing process, including the gigafactory.

Once built, Verkor’s first gigafactory will produce low-carbon battery cells designed to support Europe’s net-zero goals, as well as create a European battery value chain of players and solutions. As part of this roadmap, the company is deploying Dassault Systèmes’ 'High Performance Battery' and 'High-Tech Smart Factory' industry solution experience based on the 3DexperienceE platform for seamless collaboration, modelling and simulation in one virtual environment.