The great advantage of this type of technology is that it allows for ultra-fast charging, where it can reach the vehicle's maximum range in just 10 minutes, greater safety, and a useful life that can be up to three times longer than conventional batteries.

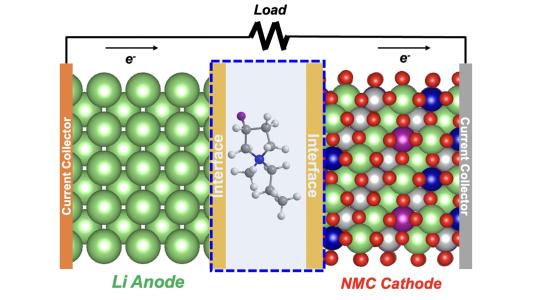

Brazil-headquartered CBMM, a world leader in the production and commercialisation of Niobium products, and Japan's Toshiba worked for six years as part of collaborative efforts to develop mixed Titanium oxide technology in which Niobium is added to the anode in lithium-ion battery cells, a development known as NTO. Later, in 2021, the project was expanded through a partnership with Volkswagen Truck & Bus. The company is a pioneer in electric vehicles development in Latin America, which led to this innovative battery being used in an electric bus through the development of thermal, energy and ultra-fast charging management systems.

The technology will be validated and improved during this real operation at CBMM, where the vehicle will run on a daily basis along a fixed route, with recharging on the pantograph scheduled at the beginning or end of the journey. The operation will allow data to be obtained on both the characteristics of the NTO battery and the vehicle to identify any adjustments needed before future commercialising the product.

“Seven years ago, we surprised the market with the first electric truck prototype made in Latin America,” said Roberto Cortes, President and CEO of Volkswagen Truck & Bus. “Now, we are once again anticipating global trends and seeking to lead the transformation of the industry, with reference partners such as CBMM, which will also support us by receiving our prototype for tests in real operation at its plant in Araxá."

Configured on an 18-ton chassis, the prototype bus has an estimated range of 60 kilometres and can be recharged in 10 minutes when a 300-kW pantograph is used. It is equipped with four packs of lithium batteries in which Niobium is added to the battery’s anode, each with a useful capacity of up to 30kWh. Among the advantages of this system, its NTO anode structure allows it to withstand ultra-fast charging and may be operated in milder temperatures. This increases battery life, safety and generates a reduction in energy consumption due to a reduced demand for system cooling.

The testing period is indefinite and will be defined according to the evolution of the application. Over the medium term, testing is expected to be expanded to a small fleet for validation. At this stage, all components will be monitored in real time to analyse their behaviour and support processes aimed at improvement and development of the technology. Only after this phase will it be possible to determine the next steps to be taken for launch of the electric bus. Batteries fitted with NTO technology are expected to be available on the market in 2025.